Modern OEMs don’t just create. They innovate. The secret to innovation is having the right data. The right data strategy helps you reduce downtime, improve product quality, serve customers faster, and drive real ROI.

Here’s a breakdown of the essential data categories every OEM should be tracking - and why they matter.

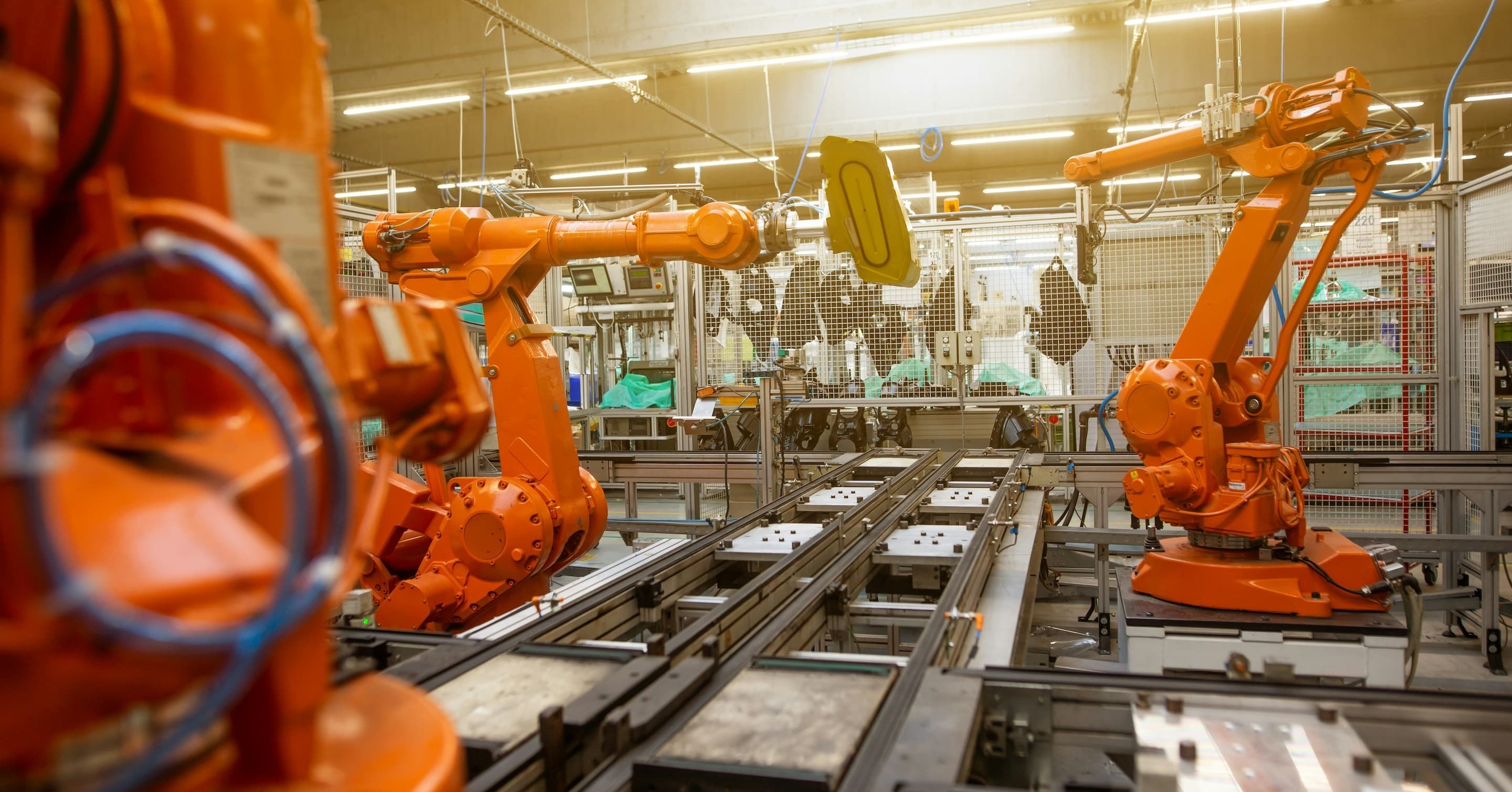

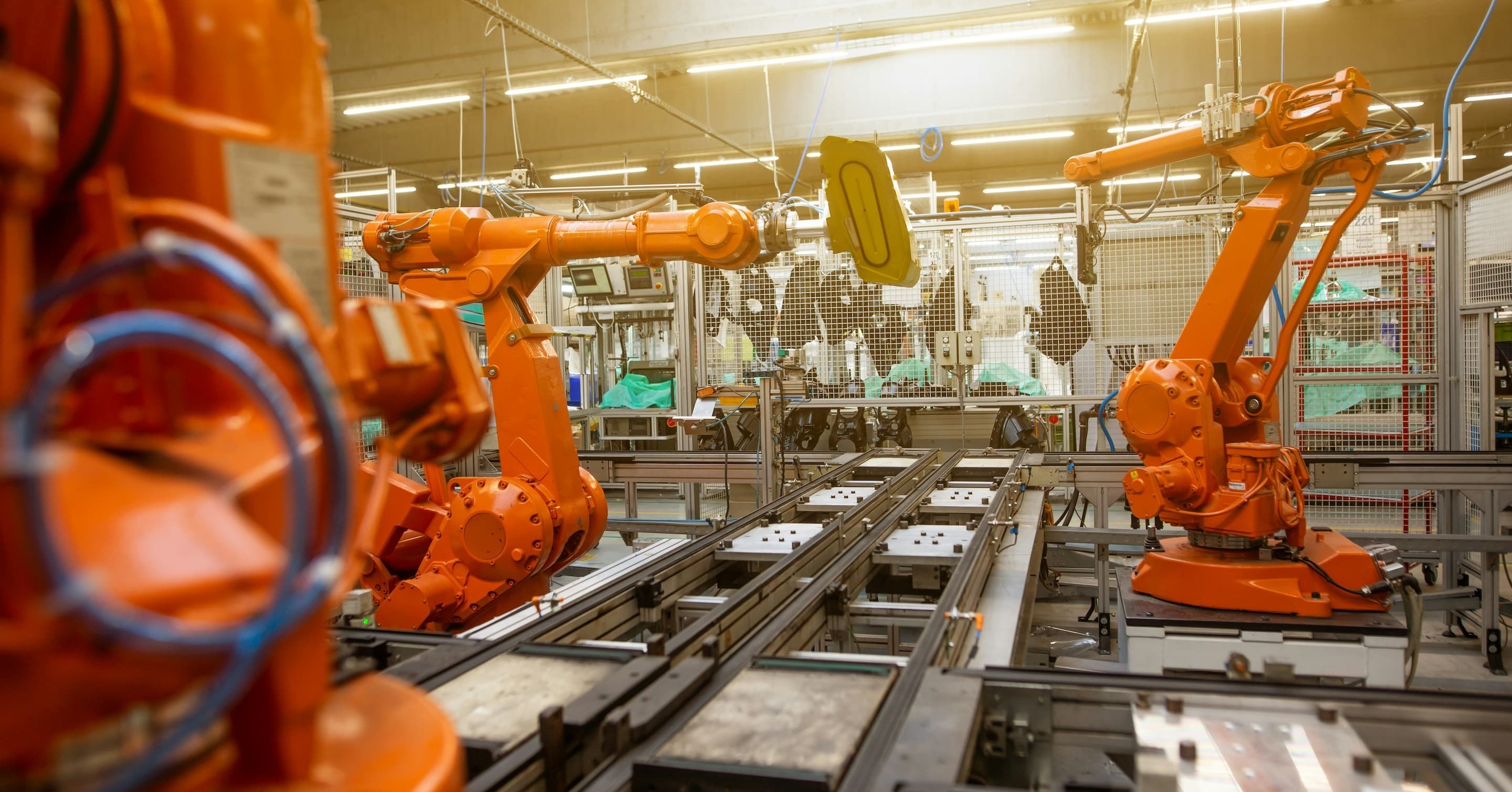

Manufacturing Data

Your production floor is full of untapped insights. Metrics like cycle times, scrap rates, and operator-specific performance help you understand where bottlenecks or inefficiencies exist, so you can take targeted action.

Downtime tracking is particularly important. Whether it’s planned maintenance or unexpected stoppages, logging when and why downtime occurs allows you to uncover trends, reduce interruptions, and ultimately boost productivity.

With accurate manufacturing data, OEMs can make better decisions on scheduling, resource allocation, and equipment investments. It's the foundation of a more agile and responsive factory.

Manufacturing metrics to track:

- Cycle times

- Scrap rates

- Operator-specific metrics

- Downtime tracking

Related Content: Make Sense of Your ERP Data Using Power BI

Supply Chain & Inventory

Your supply chain is only as strong as the visibility you have into it. Tracking supplier performance - including on-time delivery rates, quality metrics, and order accuracy - helps you manage risk and build accountability.

Real-time inventory levels and lead time data ensure you’re stocking the right parts at the right time without overbuying or delaying production. Especially in today’s volatile market, having this visibility allows you to pivot quickly and maintain flow through your operations.

Better supply chain and inventory data support better forecasting, less waste, and stronger profit margins.

Supply chain & inventory metrics to track:

- Supplier performance metrics

- Inventory levels

- Lead times

Customer & Field Service

The customer relationship doesn’t end at the sale - so your data collection shouldn’t either. Warranty claims and repair logs help you spot recurring issues, which feeds back into product design and quality control.

If your equipment includes smart or connected features, remote diagnostics can alert your service team to issues before your customers even call. That reduces downtime and builds trust.

Tracking satisfaction scores and service contract renewals also gives you a better picture of lifetime customer value and helps identify opportunities for upselling, training, or proactive support.

Customer & field service metrics to track:

- Warranty claims & repair logs

- Customer satisfaction scores

- Remote diagnostics (if applicable)

- Service contract renewals (if applicable)

Regulatory & Compliance Data

Staying compliant with safety, environmental, and quality standards requires reliable, well-organized data. Capturing health and safety incidents, environmental impact logs, and QA/inspection data keeps you compliant - and can help uncover root causes of issues that affect both your operations and your brand reputation.

Proactively tracking and analyzing compliance data not only protects you from fines and delays but can also be a valuable asset in competitive bids and customer relationships.

Regulatory & compliance metrics to track:

- Health, safety, and environmental logs

- Inspection & QA data

Whether you're modernizing your factory or expanding your aftermarket strategy, collecting the right data is step one. With clear insights across your operations, you can make smarter decisions - and build stronger customer relationships.

Turn Insights Into Action

Ready to put your data to work? Let’s talk about how we can help you collect, connect, and capitalize on the metrics that matter most for your OEM.

Superior Consulting Services (SCS) is a Microsoft-centric technology firm providing innovative solutions that enable our clients to solve business problems. We offer full-scale data modeling, analytics and custom app development.